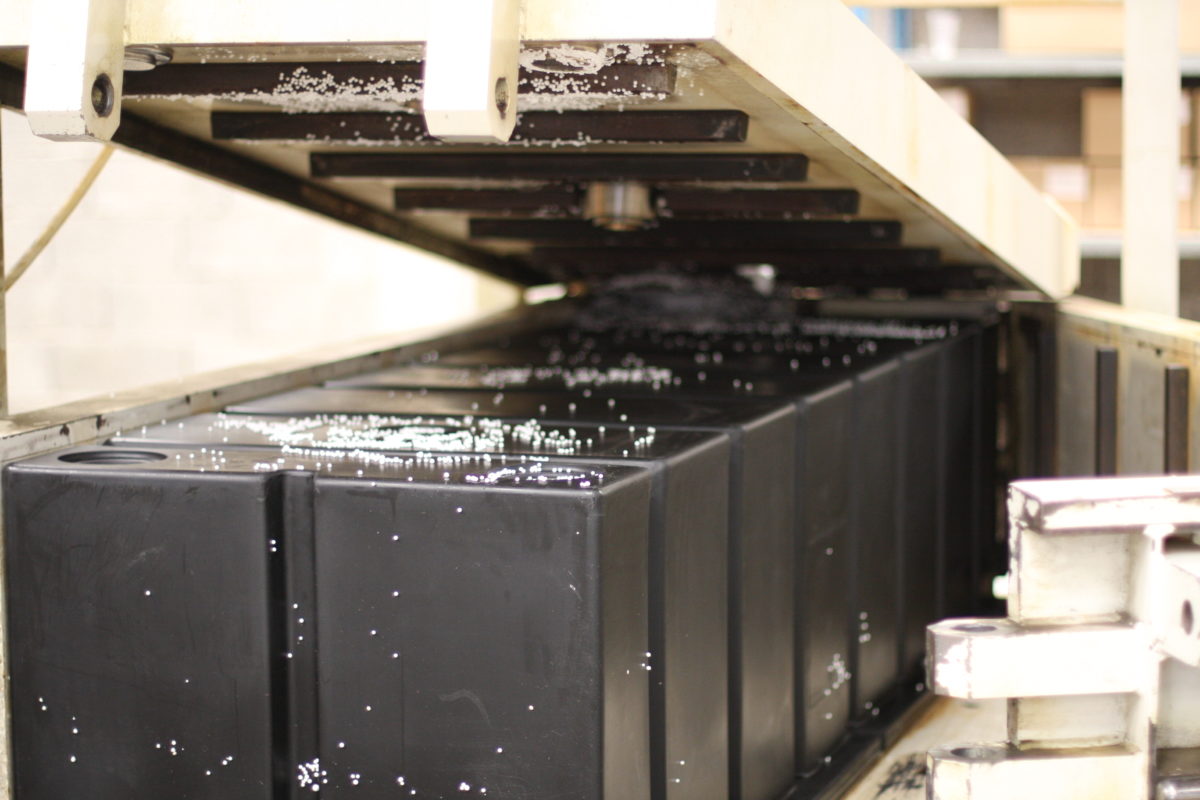

Polyethylene dock floats

In order to further guarantee the quality of our polyethylene dock floats, we manufacture our own roto-moulded floats. They are filled with expanded polystyrene foam and guaranteed unsinkable thanks to our experience and expertise in foaming techniques.

Poralu Marine floats are available for docks, fingers and mooring arms. They are a 100% recyclable dock equipment.

Our floats are resistant to shock and punctures and are unaffected by electrolysis. As a roto-mould, they are a fully enclosed, one-piece structure, with no welds or cover. They are built to last.

Additional technical characteristics of our floats include the following:

- The density of the polystyrene is between 16 and 20 kg/m3.

- Absorption rate of less than 5%.

- Polystyrene is rated as M1 fire retardant.

Depending on the various needs of each installation, a trough or service channel is integrated into the floats in order to have water lines and electrical cables to run above the floatation, which allows for easy installation and service for mechanical and electric services.

Poralu Marine floats benefit from an exclusive and patented buoyancy compensation system. Our system of buoyancy compensation allows for additional loads to be added to the docks without the need to replace floatation. For example, if a new electrical distribution box is installed on the dock, the additional weight would require additional floatation to ensure the dock remains balanced and stable. With our patented system, this is a simple process with the installation of buoyancy compensators on the existing floatation.

In terms of installation of the floats themselves, they are housed inside the dock in an aluminium rail welded to the structure. The floatation is well distributed throughout the dock. Outside the dock, the floats are held in position with aluminium screws.